Coppercraft Distillery is a proud partner of the Detroit Lions. Find our limited edition Honolulu Blue in celebration of our #OnePride.

Coppercraft is a proud partner of the Orlando Magic. Find our limited edition 407 Bourbon and discover Magic in every Sip.

Building upon Michigan’s legacy of high-quality craftsmanship, we artfully distill, source, and blend the finest ingredients to craft premium spirits.

Straight Bourbon Whiskey

Small Batch

48.5%

97

750

Blend of Straight Bourbon Whiskies

Small Batch

50%

100

750

Rye Whiskey

Small Batch

45%

90

750

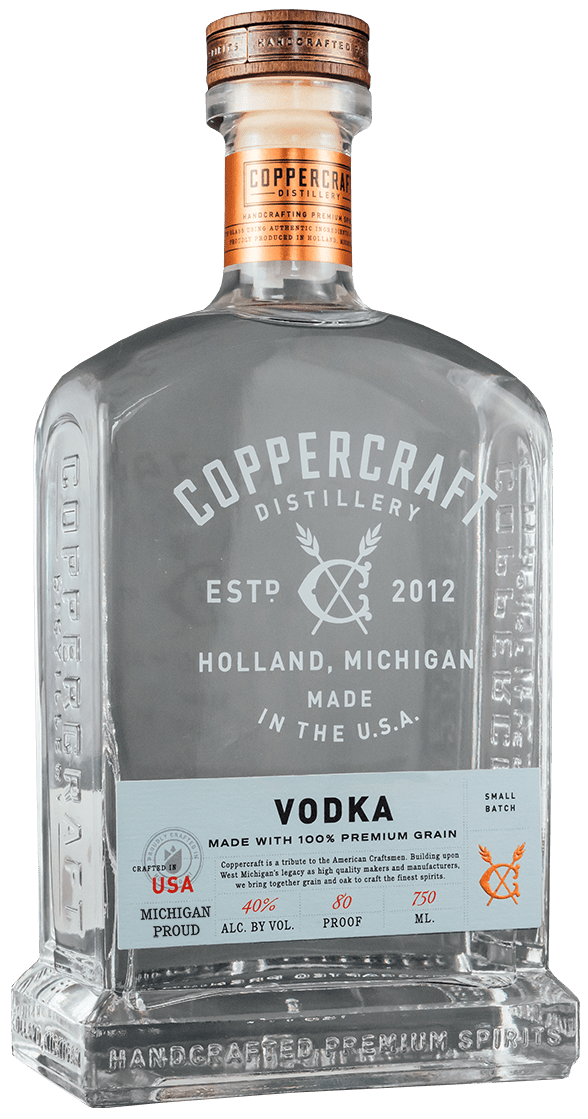

Vodka

Made with 100% premium grain

Small Batch

40%

80

750

Single Barrel Straight Bourbon

Small Batch

Varies%

Varies

750

Gin & Tonic

Crafted Premium Cocktail

Small Batch

10%

355 mL/(12oz)

Contents

Whiskey Lemonade

Crafted Premium Cocktail

Small Batch

10%

355 mL/(12oz)

Contents

Pink Bubbles

Crafted Premium Cocktail

Small Batch

10%

355 mL/(12oz)

Contents

Visit Us

- Tasting Room

- Distillery & Tasting Room

- Private Events

HOURS

Closed for the season

Hours

TUES – THURS: 4PM – 8PM

FRI – SAT: 12PM – 8PM

SUN – MON: CLOSED

Private events, tastings, tours, weddings, classes, corporate meetings, and experiences of all shapes and sizes.

Featured Recipe

Bourbon Pineapple Smash

- 2 oz Coppercraft Straight Bourbon Whiskey

- 1 oz pineapple juice

- .5 oz lime juice

- .5 oz honey syrup

- Club soda

- Mint sprig, garnish

Combine the Coppercraft Straight Bourbon Whiskey, pineapple juice, lime juice, and honey syrup in a shaker with ice. Shake vigorously for about 15 seconds. Strain the cocktail into a rocks glass with ice. Top with club soda. Garnish with a sprig of mint.